Customized Packages

Nitrogen & Oxygen Generators

Together with compressed air, nitrogen is one of the most widespread utilities in industrial productions.

The inert property of this gas has led to its diffusion, especially in Oil & Gas and petrochemical industries, for safety reason when raw materials and products are potentially explosive and installation areas are classified as dangerous; in chemical, food, steel industries where oxidation could damage the production or interfere with critical processes.

Sinergia nitrogen generators can be supplied:

- Depending on selected technology: On skid, in container, turnkey plant version

- Stand-alone unit, or integrated with instrument air production

- Suitable for safe or explosive classified areas

- Suitable for extreme ambient installation

- Selected for intermittent or continuous production

- Selected for generating N2 from 95% to 99,999%purity

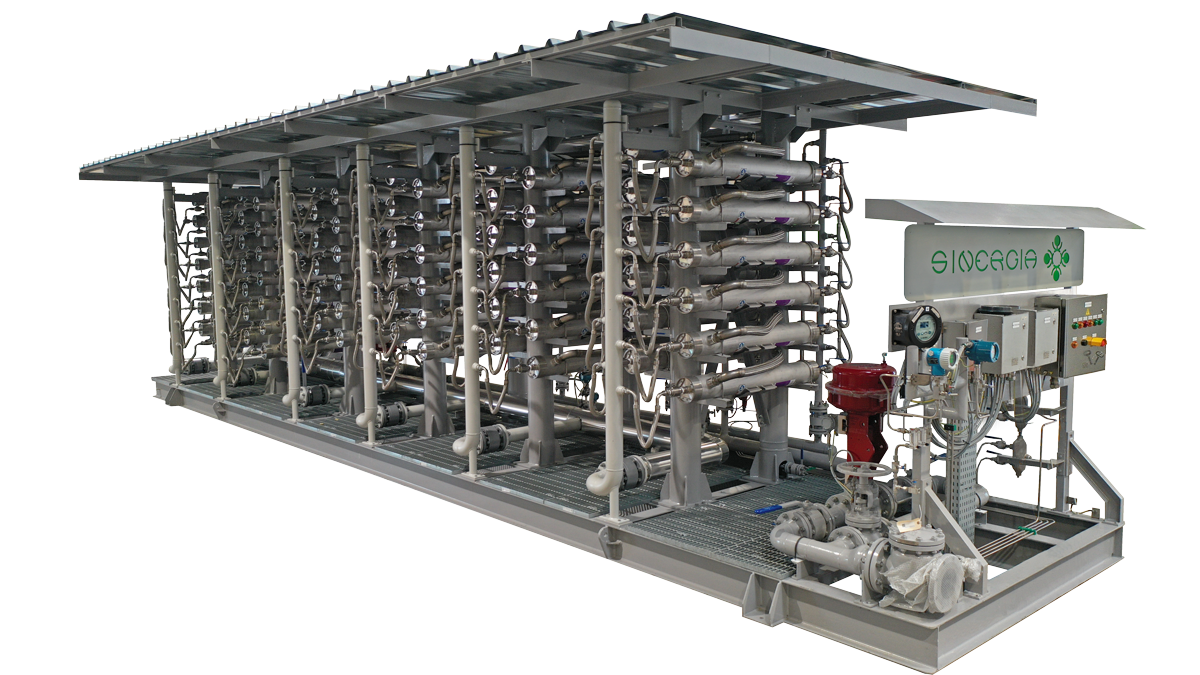

Membrane generator

The selective permeation property of membranes are suitable to separate/concentrate gaseous molecules. Sinergia can supply fully packaged membrane nitrogen generators by selecting the membrane, core of the process, among the international premium brand manufacturers. Sinergia uses advanced calculating software for the selection of the most effective membrane under the peculiar project conditions.

This technology can provide gaseous Nitrogen, virtually with no limits in capacity, with max purity of 99,5%.

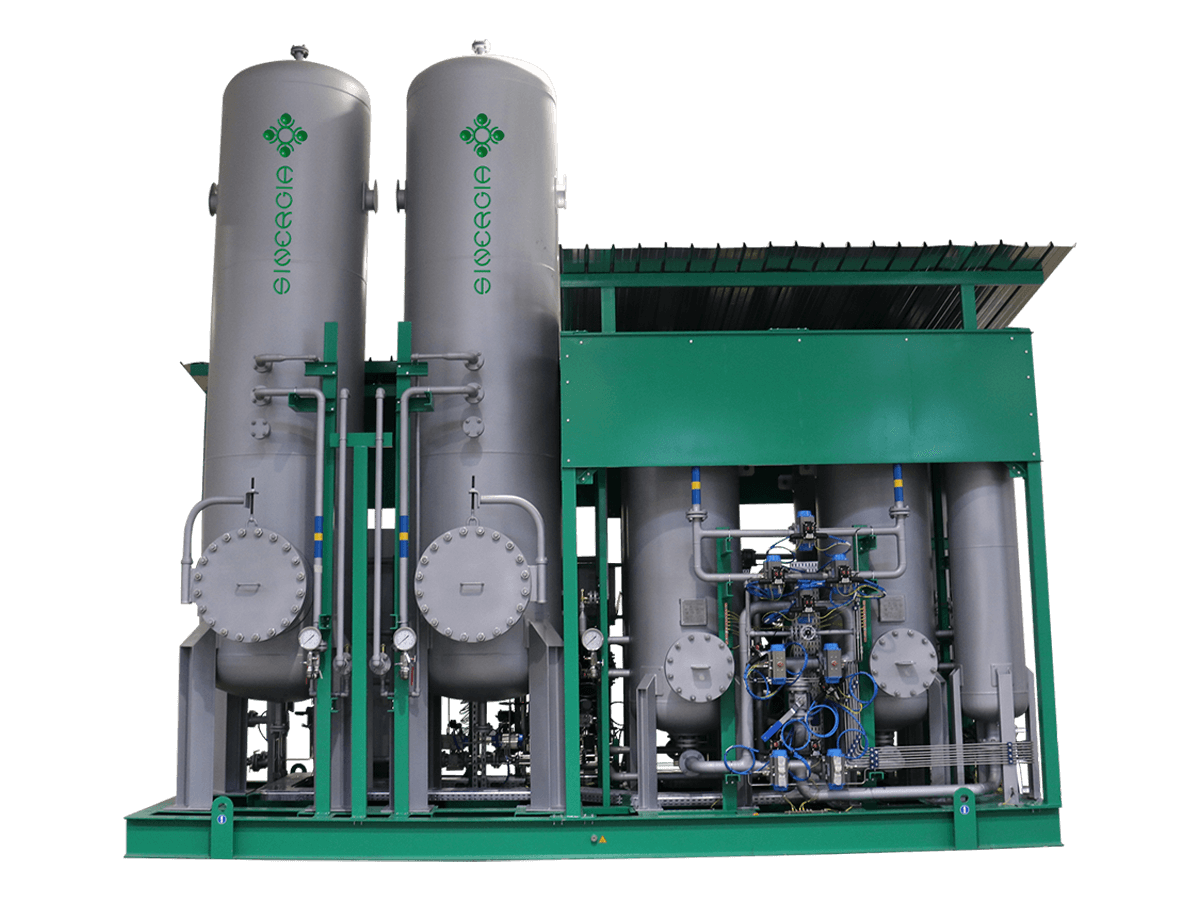

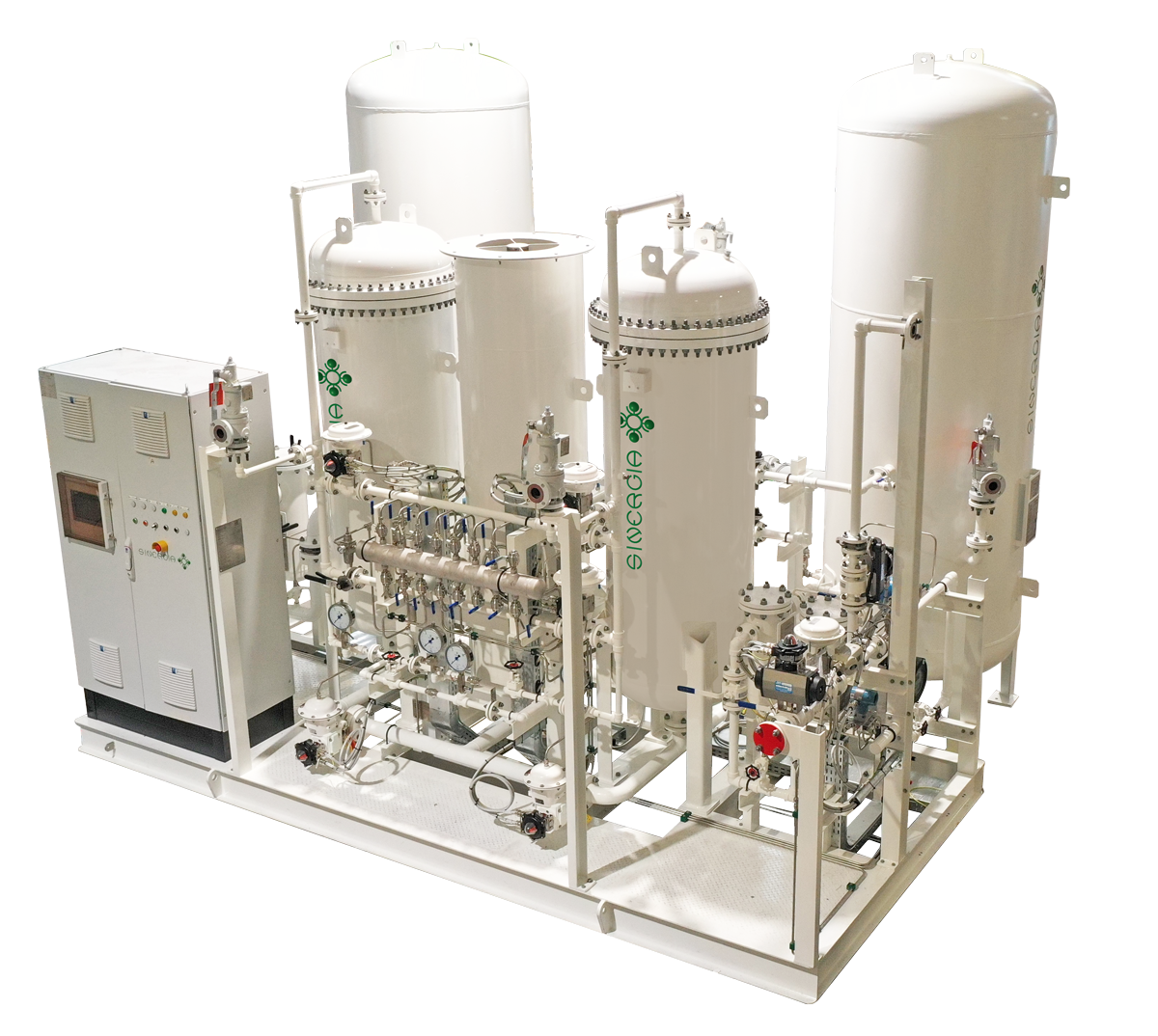

PSA generator

Sinergia has gained experience and skills in the pressure swing adsorption technology, manufacturing dryers since 2006. As a natural evolution of this know-how, Sinergia successfully started to engineer and manufacture PSA nitrogen & oxygen generators.

Sinergia selects and tests internally, on a pilot unit, the different molecular sieves, supplied by main international producers, in order to grant the optimal performance to the customer.

This technology can provide gaseous Nitrogen, with some limitation in single-unit capacity, with max purity of 99,99%.

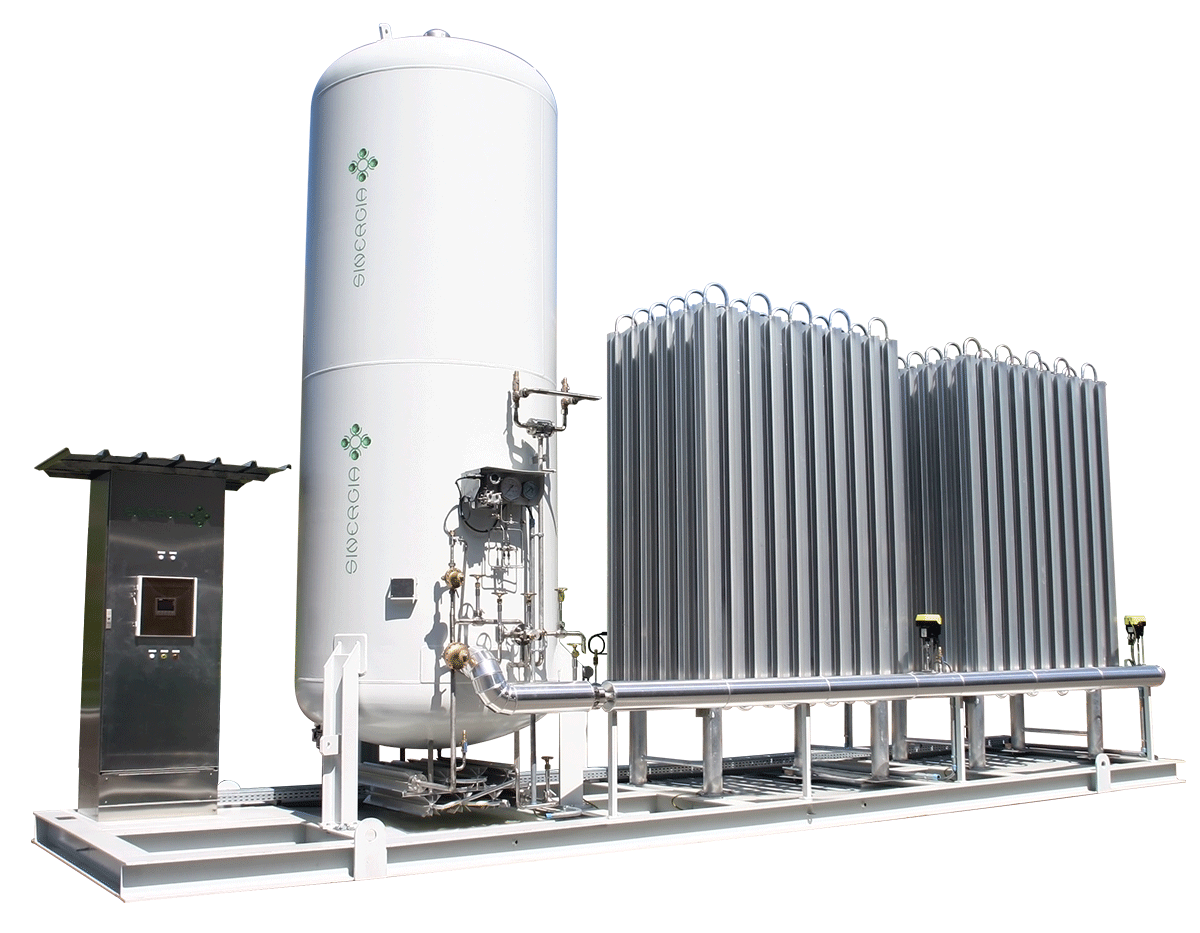

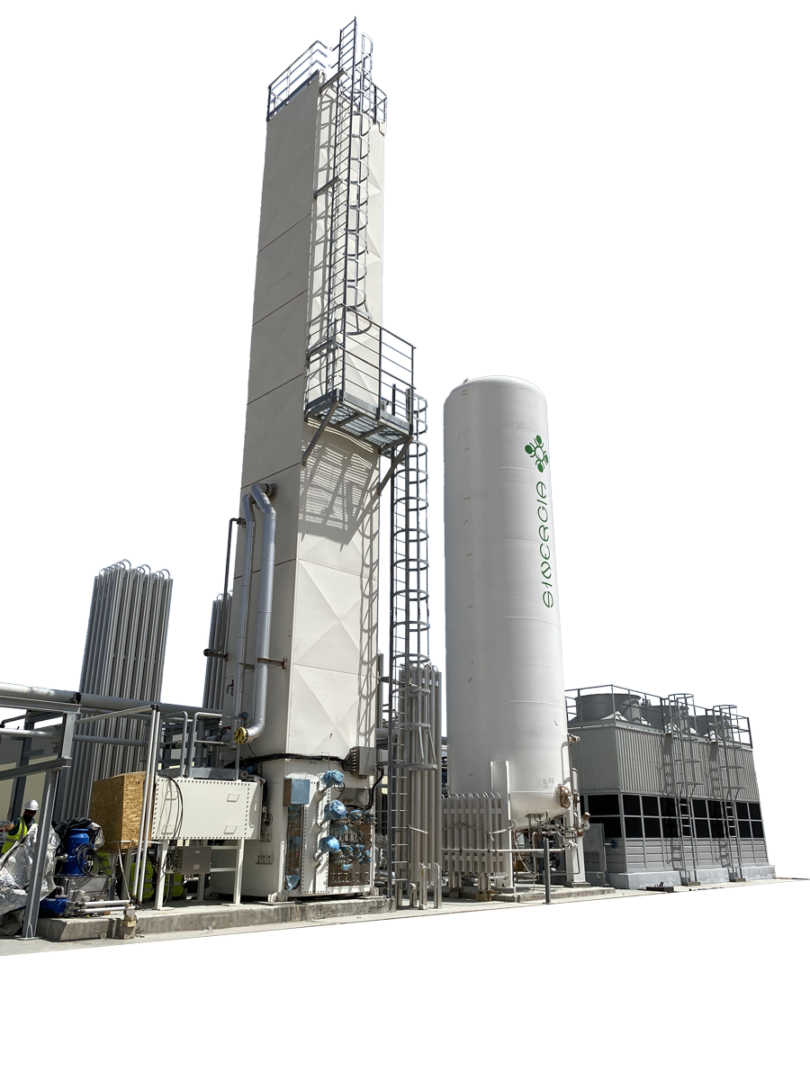

Cryogenic generator

Sinergia in recent years has fulfilled its ambition in completing the range of technologies for N2/O2 generation, by introducing in its portfolio also the cryogenic technology.

This continuous process can provide Nitrogen and Oxygen, both in gaseous and liquid state simultaneously with max.purity of 99,999%.

For more, see the Cryogenic Air Separation Plants

section in the Integrated solution chapter.