Renewable Technologies

Biomethane Package

Biogas is produced through the anaerobic digestion of organic matter such as agricultural or livestock wastes, agro-industrial wastes and the organic fraction of municipal solid waste.

This process generates a gaseous mixture composed mainly of methane (CH4) and carbon dioxide (CO2) in variable proportions, redominant compared to minor contaminants.

PROCESS STEPS:

UPGRADING

It is the purification process to obtain biomethane, from raw biogas, by removing a large portion of the CO2 and minor impurities. This can be achieved through various technologies. The one offered by Sinergia is membrane separation.

After this treatment, the gas is biomethane with a concentration of 95-98%.

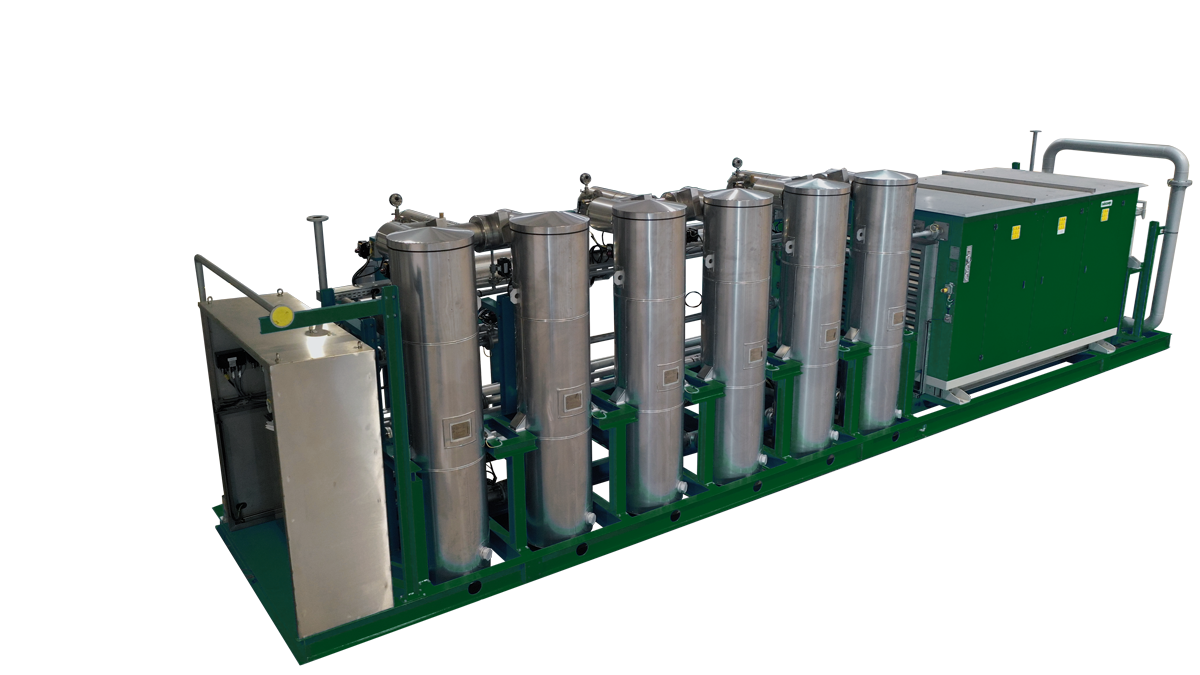

COMPRESSION

Biomethane, a gas produced at low pressure, must be compressed to be stored in tanks or injected into the network, if of suitable quality. Sinergia is able to manufacture methane compression and storage packages, suitable for this purpose.

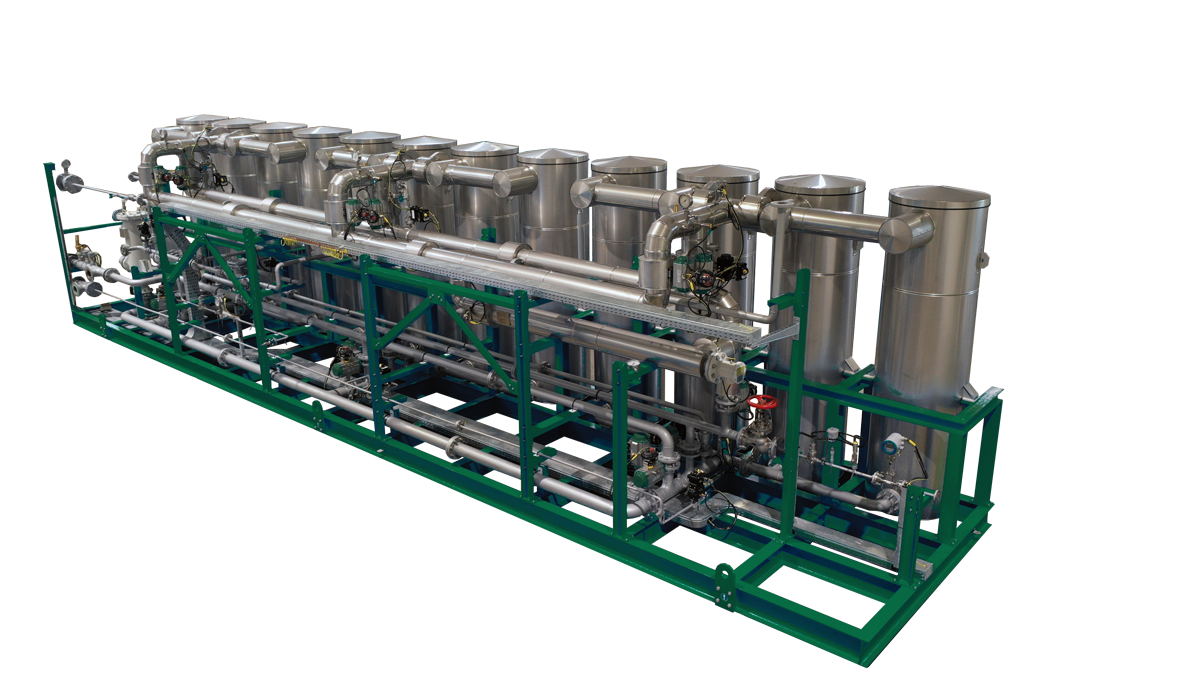

POLISHING

In the event that the purity of the biomethane must be higher than that resulting from the upgrading, making it compliant with the standards required for introduction into the network or for use as a fuel, the further removal of the present contaminants, CO2 and residual humidity can take place through the selection of other technologies. The one proposed by Sinergia is the adsorption with molecular sieves.

The obtained biomethane is a renewable gas with characteristics similar to natural gas, which can be used for energy production, heating or as transport fuel.

LIQUEFACTION

For economic convenience and safety reasons, biomethane is stored and transported in liquid form at low pressure, inside insulated tanks. The change of state occurs through cooling to approximately -162°C. Sinergia has expertise in the development of biomethane liquefaction systems through compression, progressive cooling and expansion cycle.