Ancillary Equipment & Packages

Sinergia is committed to supply turn-key integrated systems, composed of main equipment and packaged ancillary, designed and manufactured internally thanks to the wide competences of the engineering team and productive flexibility. The ambition to get full responsibility on this kind of projects has brought Sinergia to horizontally integrate its productive range with following items.

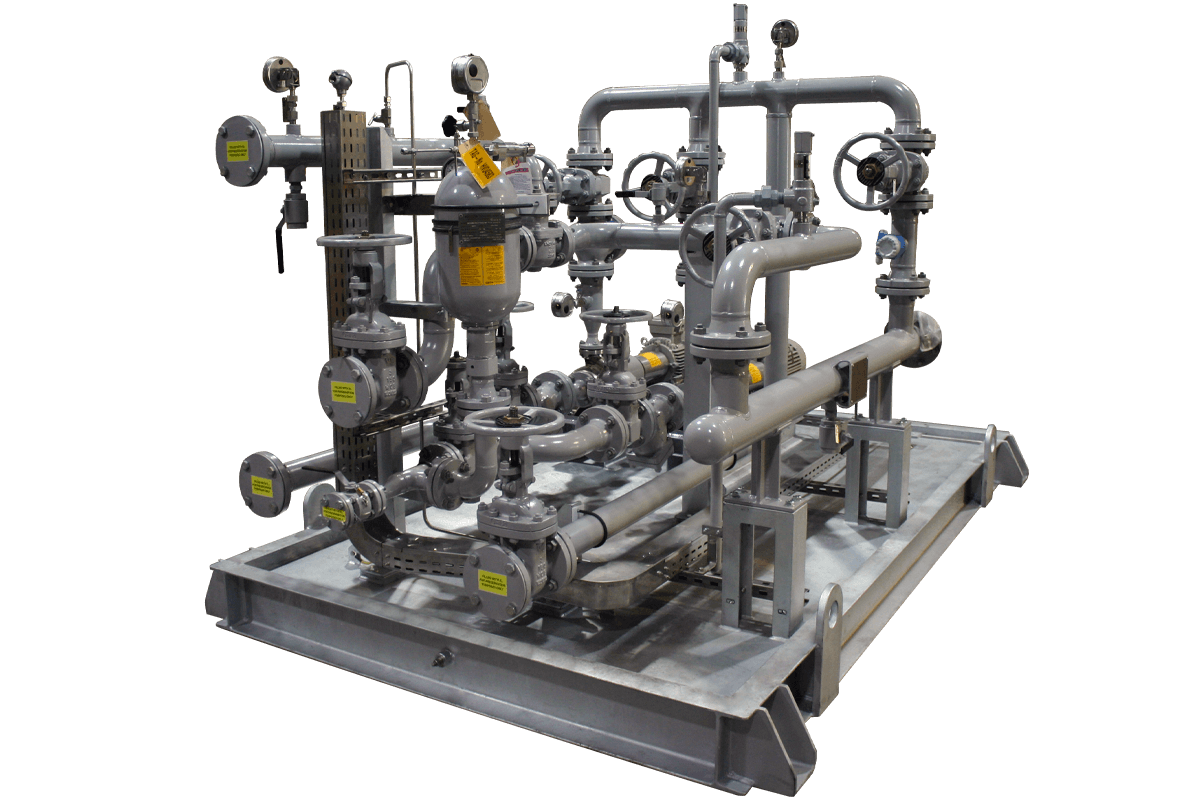

Oil & water console

Sinergia manufactures oil consoles suitable for air compressors lubrication and water consoles for water-cooled air compressors cooling. These consoles can be in single or redundant configurations. Sinergia can follow its own standard, typically applied to its packages, or customer's design and specifications.

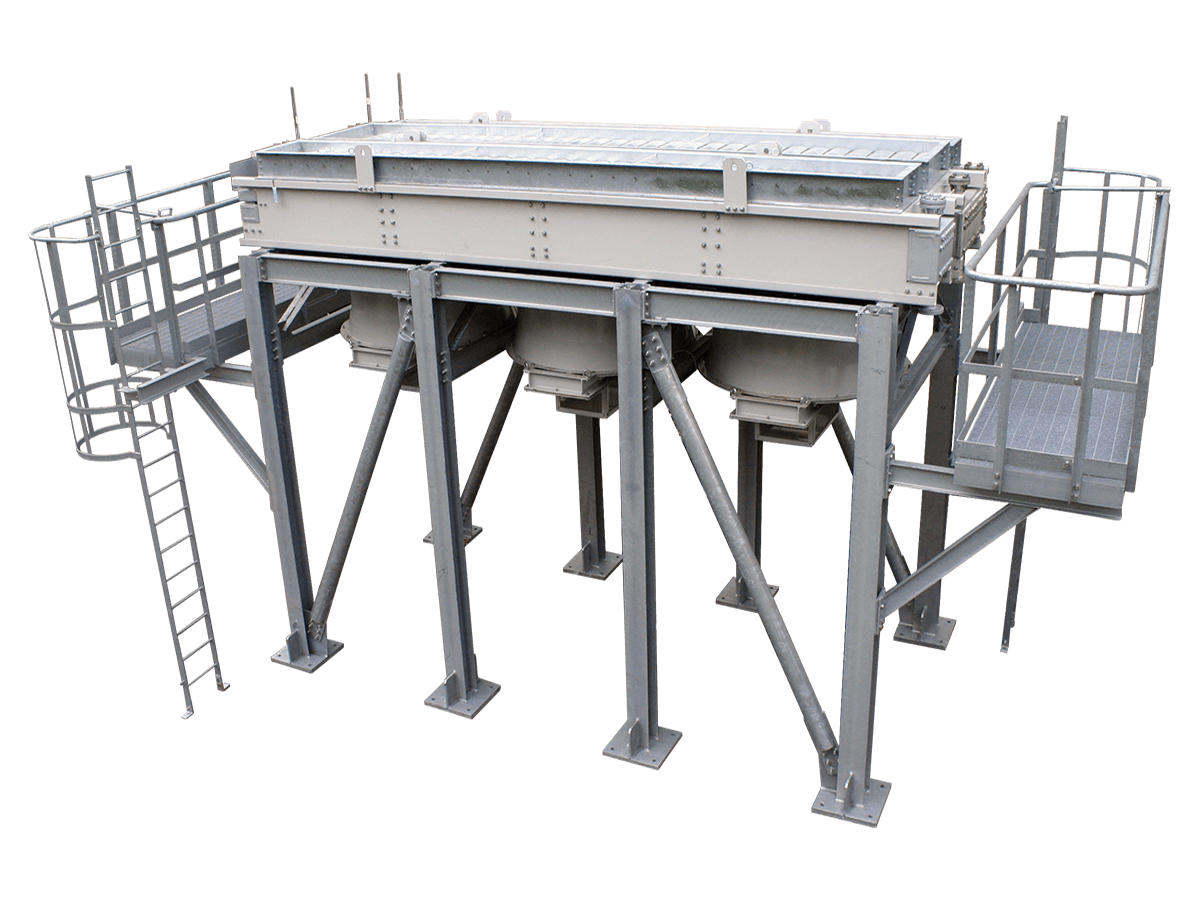

Air & water cooler

Besides API 619 screw air compressors, typically installed in areas where cooling water is not available, Sinergia manufactures the air cooling systems for air compressors having API 661 design. There is no standard line of products, but dedicated engineering to match the cooling needs of selected air compressors for each project. Moreover, Sinergia is able to develop dedicated engineering as per customer requests.

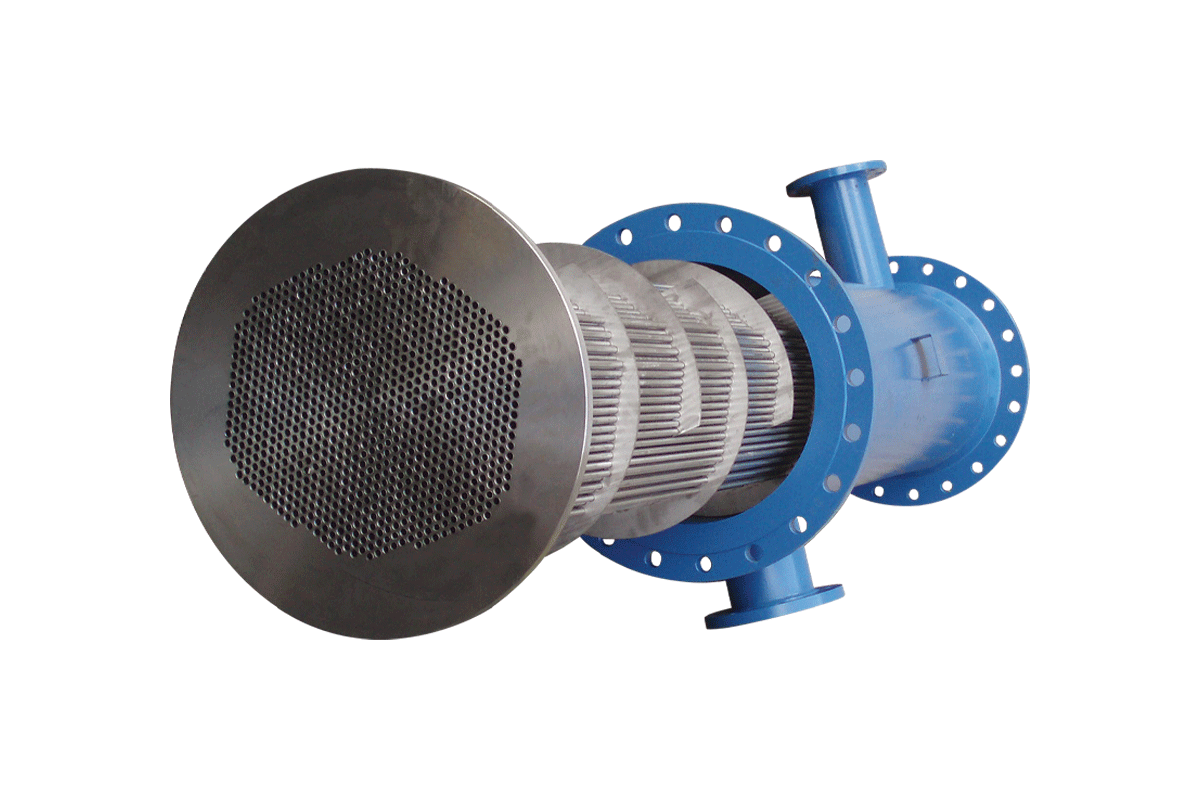

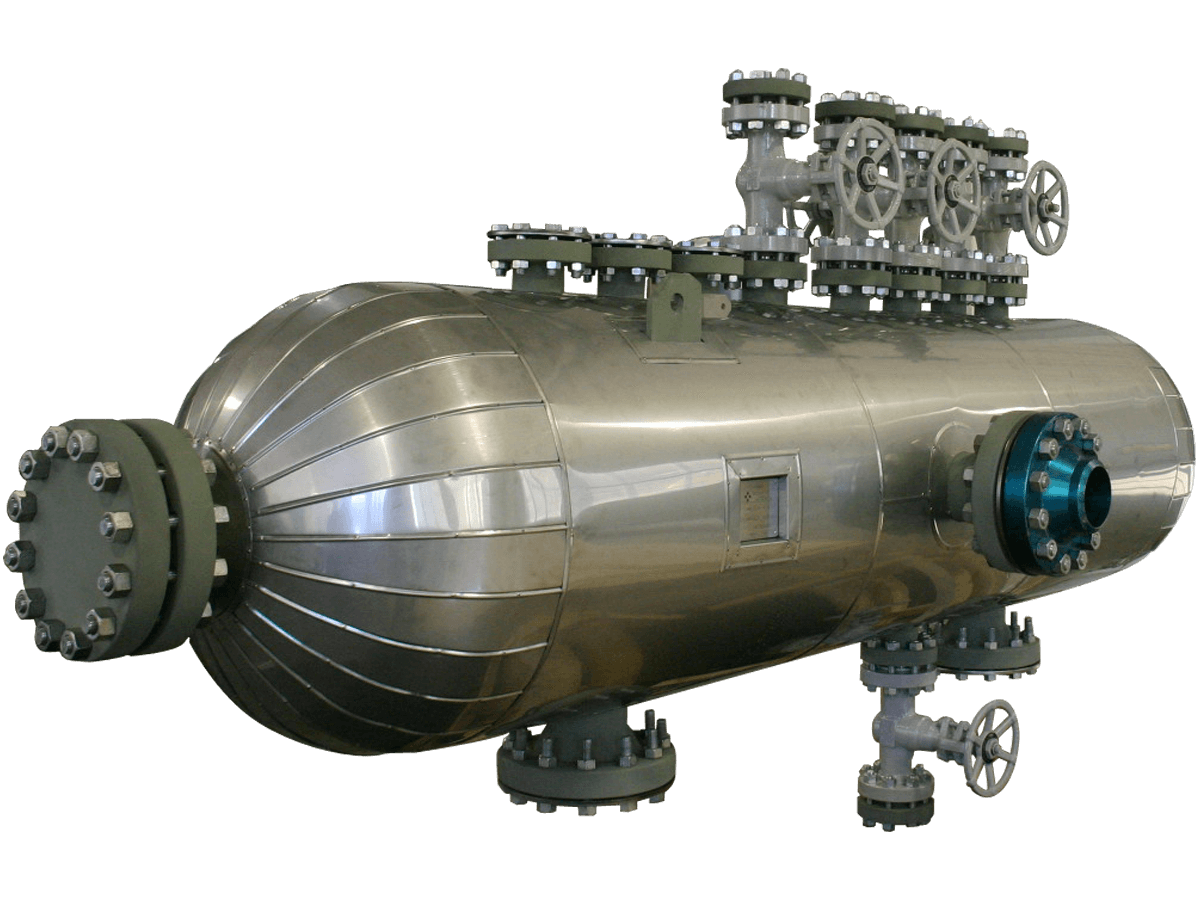

Shell & tube heat exchanger

The Shell & Tube heat exchanger is one of the most efficient temperature exchangers between two different fluids. Commonly used to reduce compressed air, gas, oil, and water temperature thanks to cooling water, can be designed and manufactured by Sinergia under API 660 - TEMA C - TEMA R - ASME (U Stamp) calculation codes.

Different materials and configurations can be supplied accordingly to customer requirements.

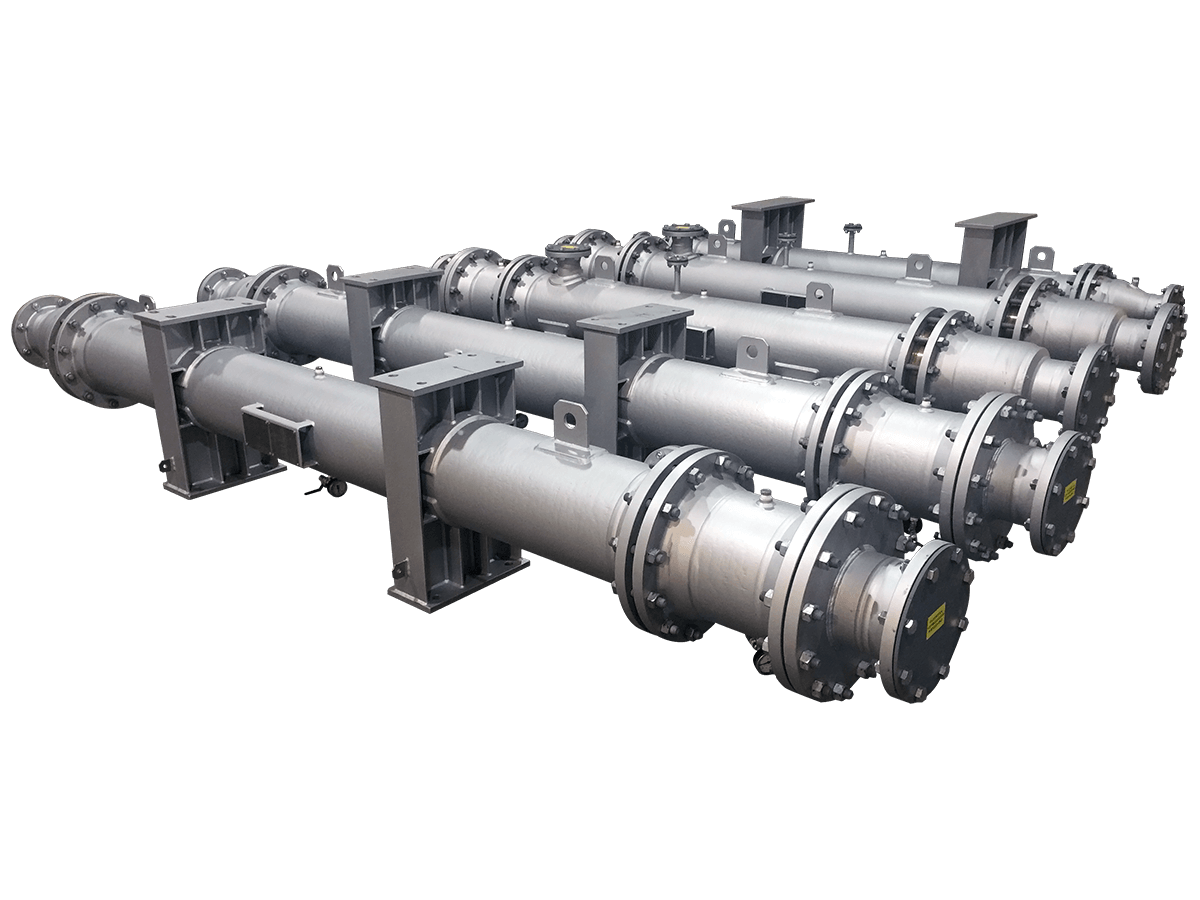

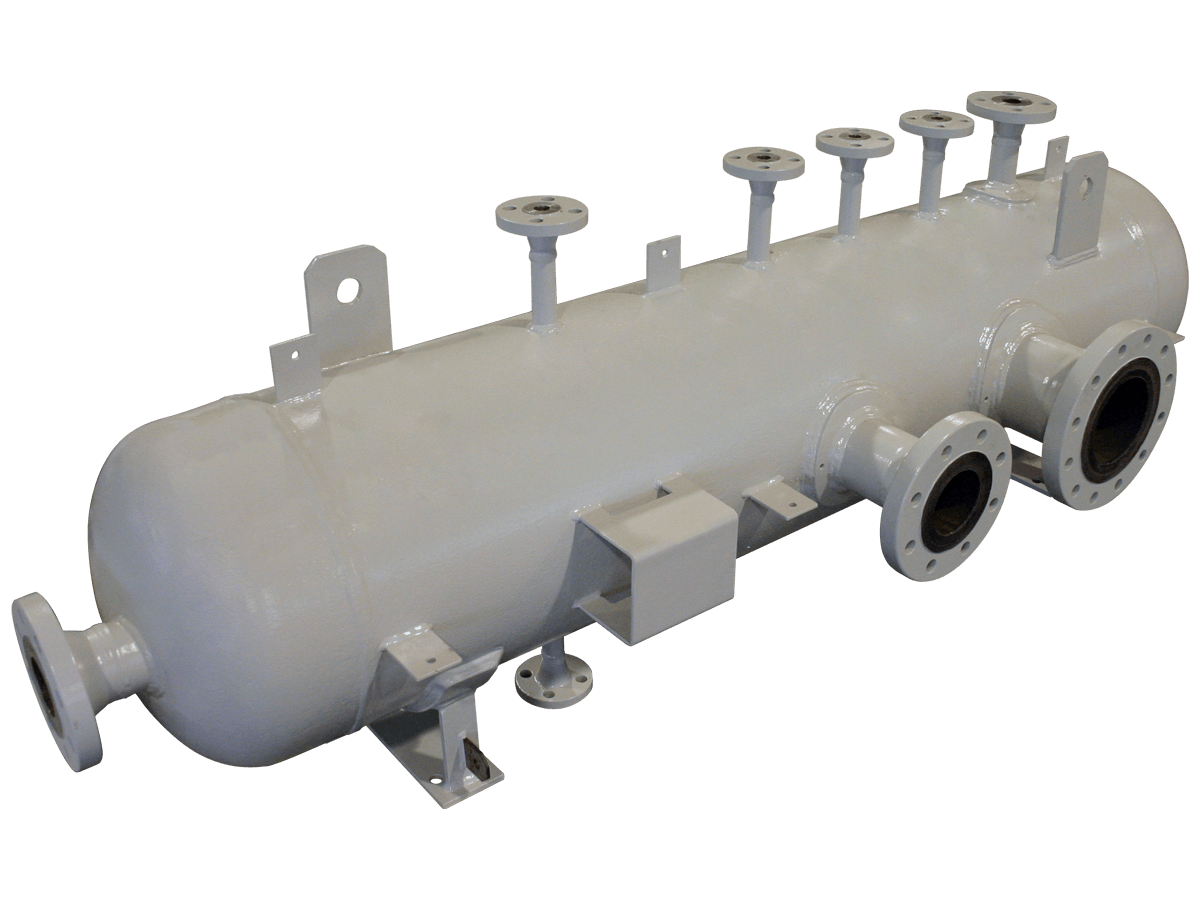

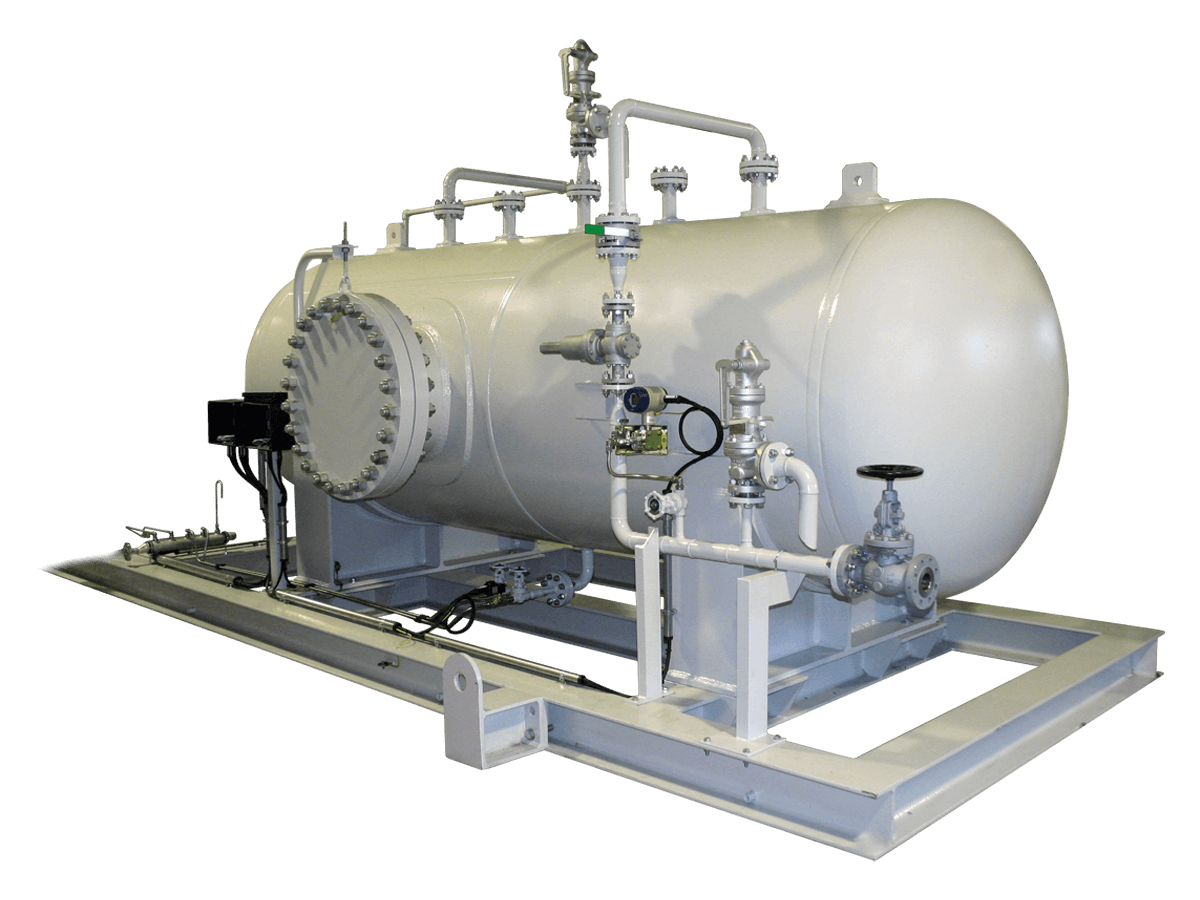

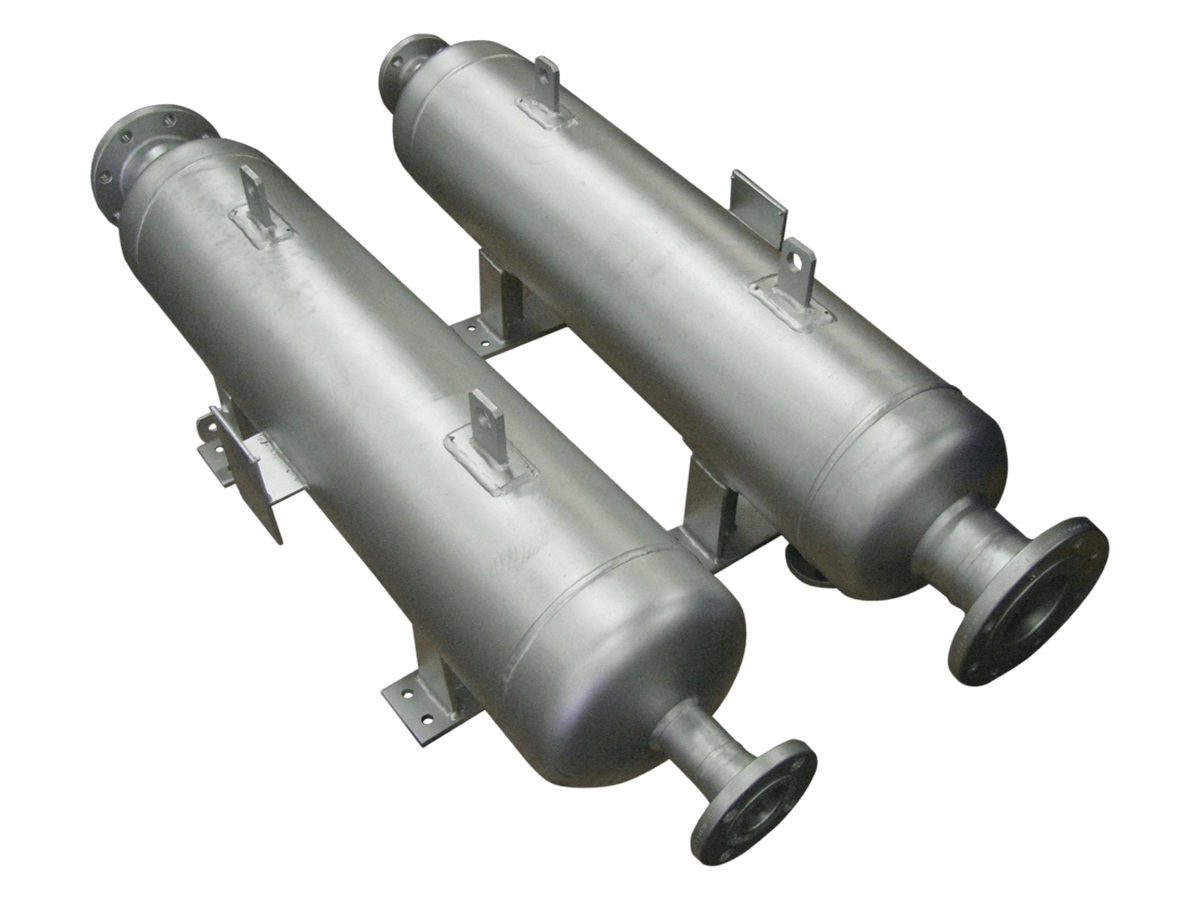

Pulsation damper

Sinergia can manufacture this specific kind of vessel usually installed upstream and downstream of the reciprocating compressor. The pulsation calculation usually supplied by the customer drives the Sinergia design of the vessel.

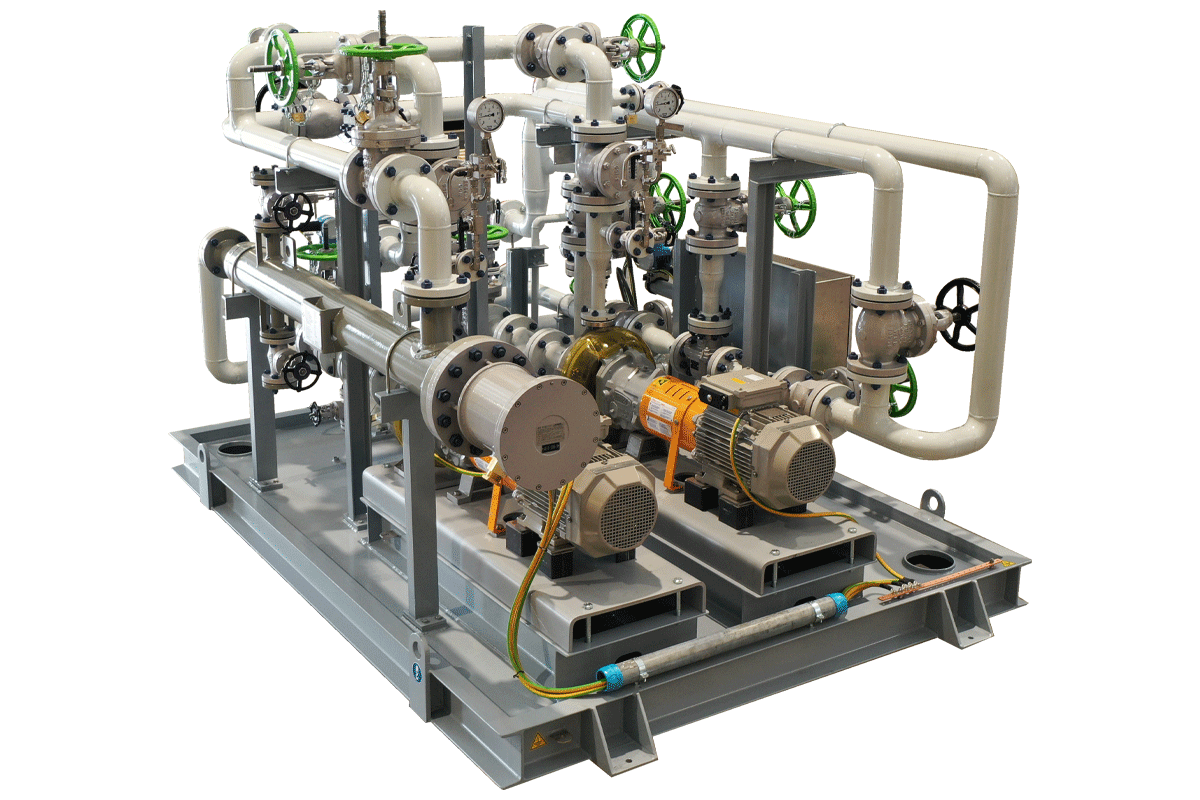

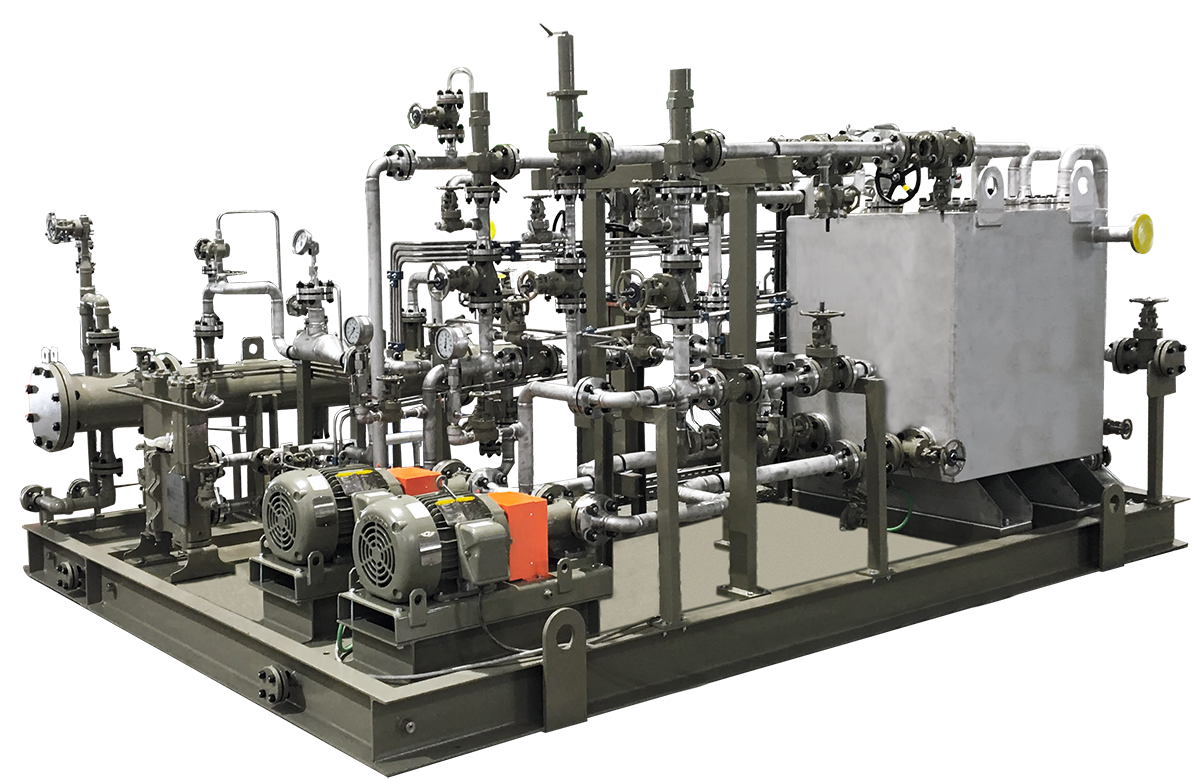

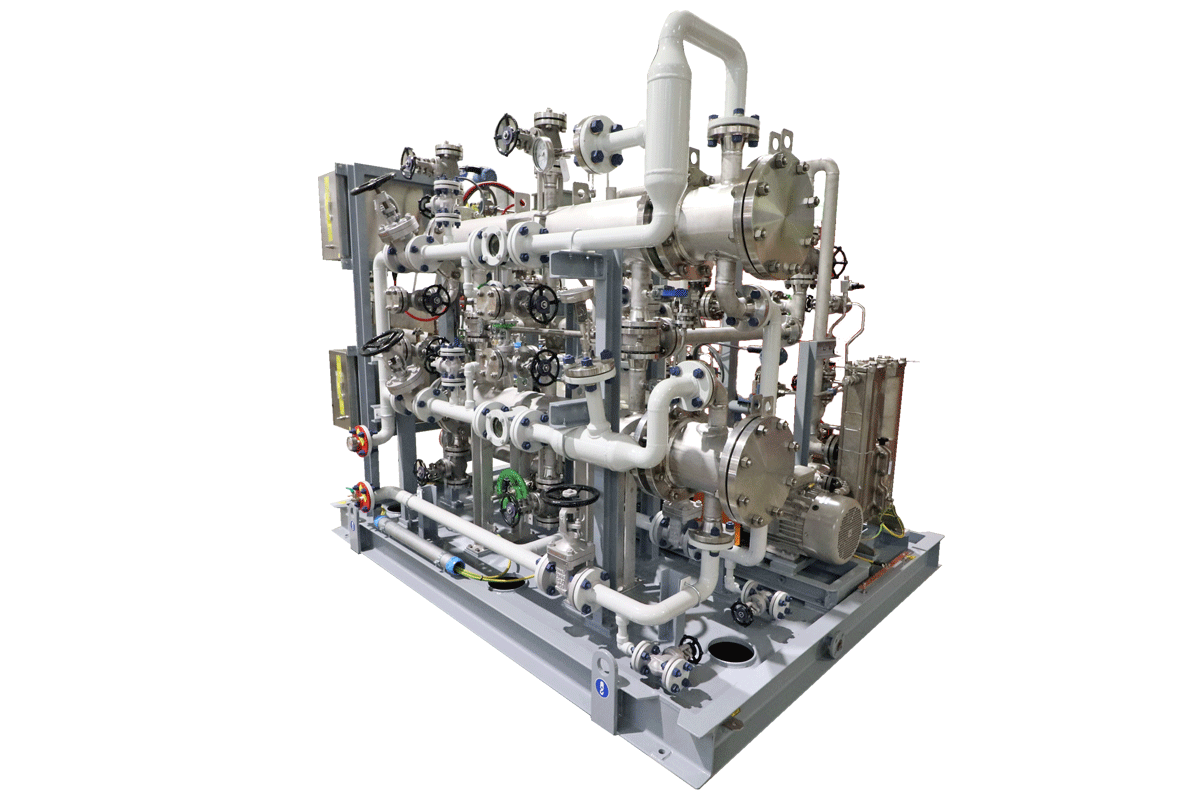

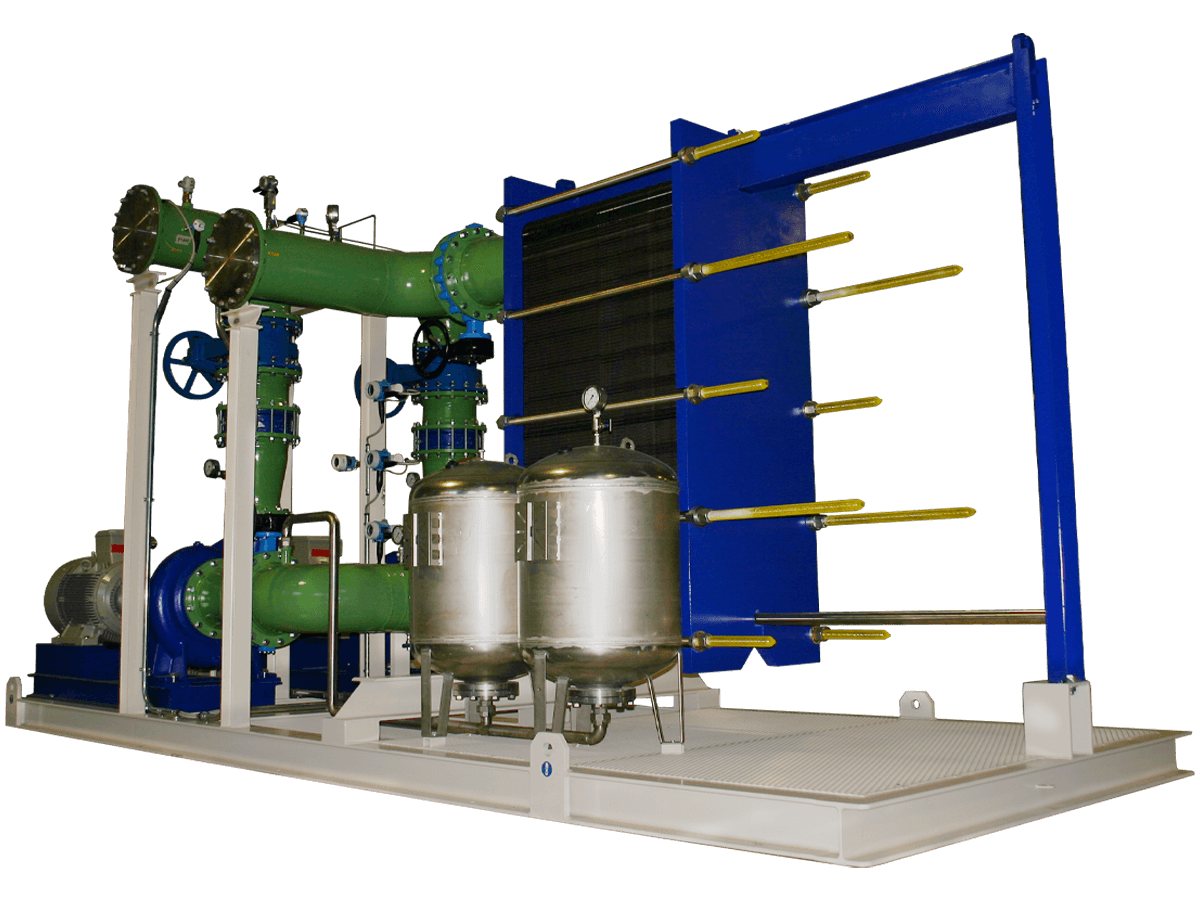

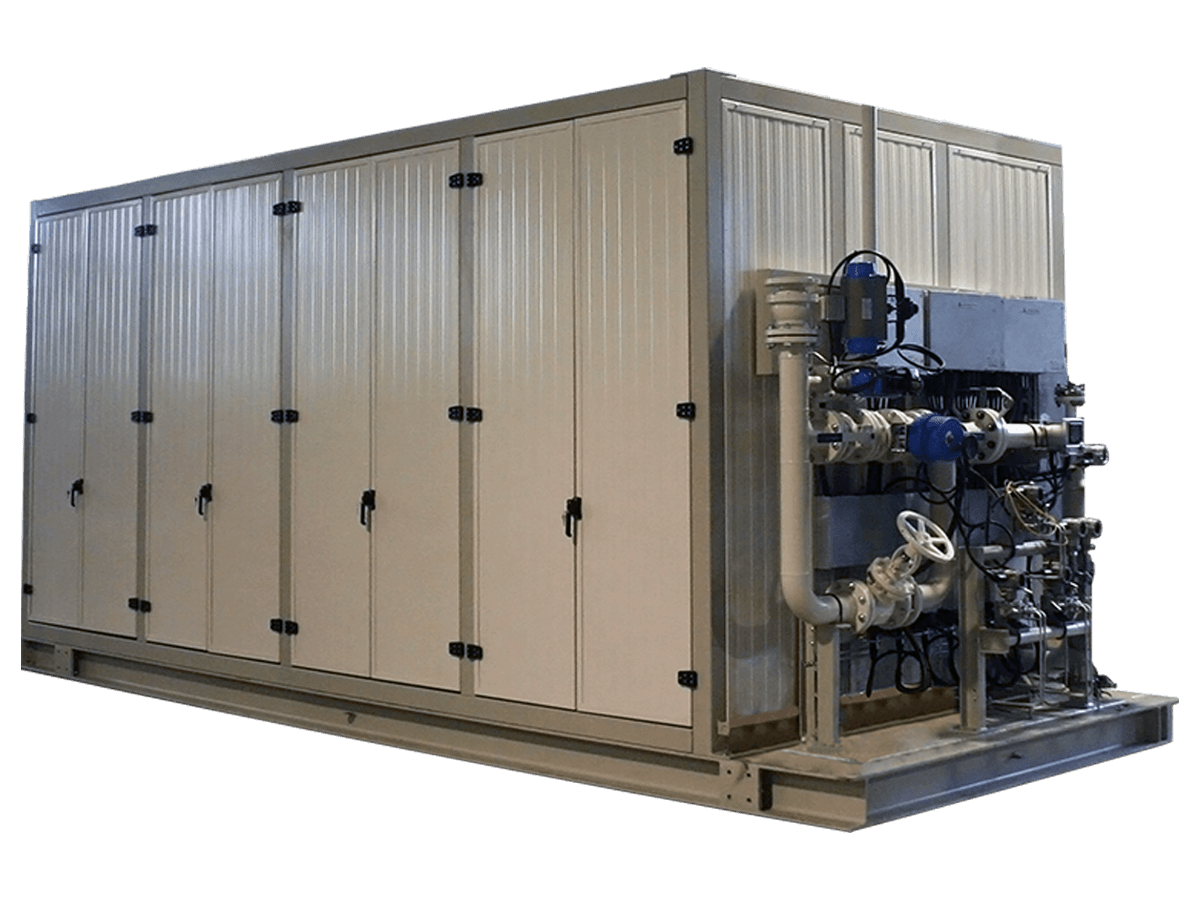

Circulating pump skid

This package is usually engineered by Sinergia to be combined with a cooling tower (out of Sinergia's scope) for water circulation with cooling purposes.

The selection of materials, and the control system, can be totally customized.

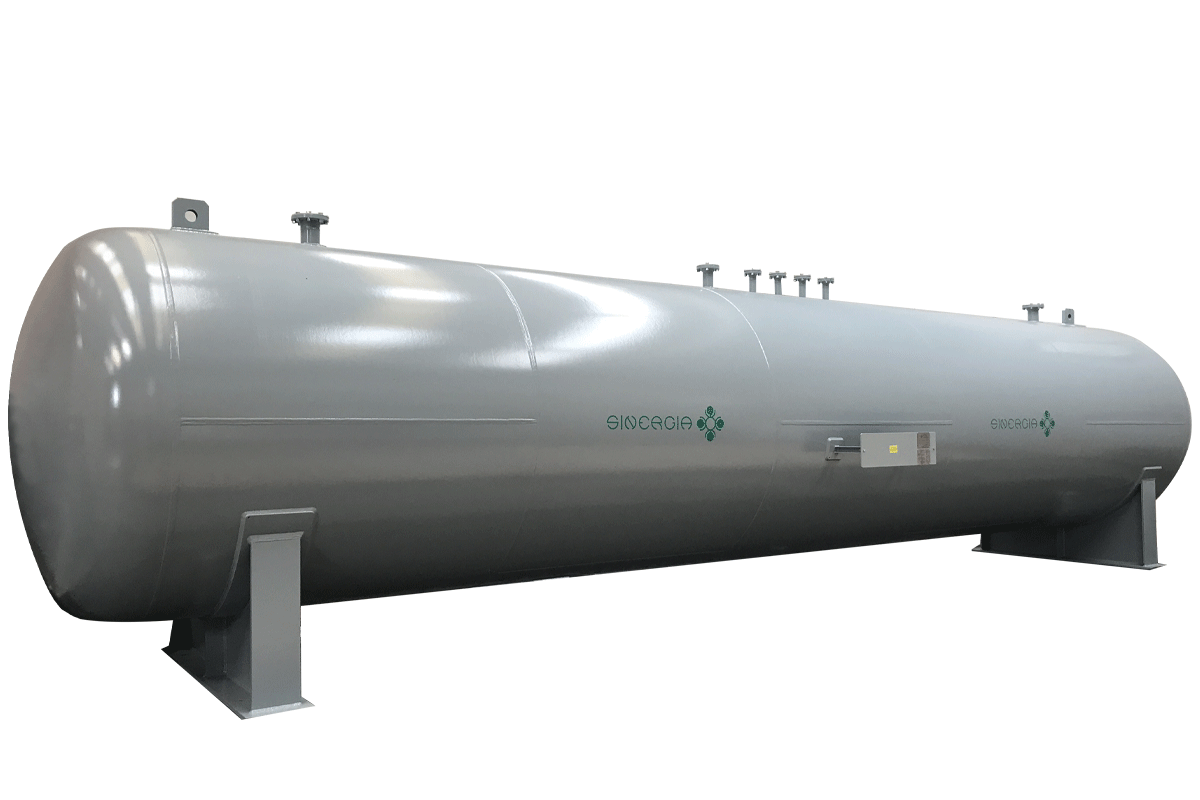

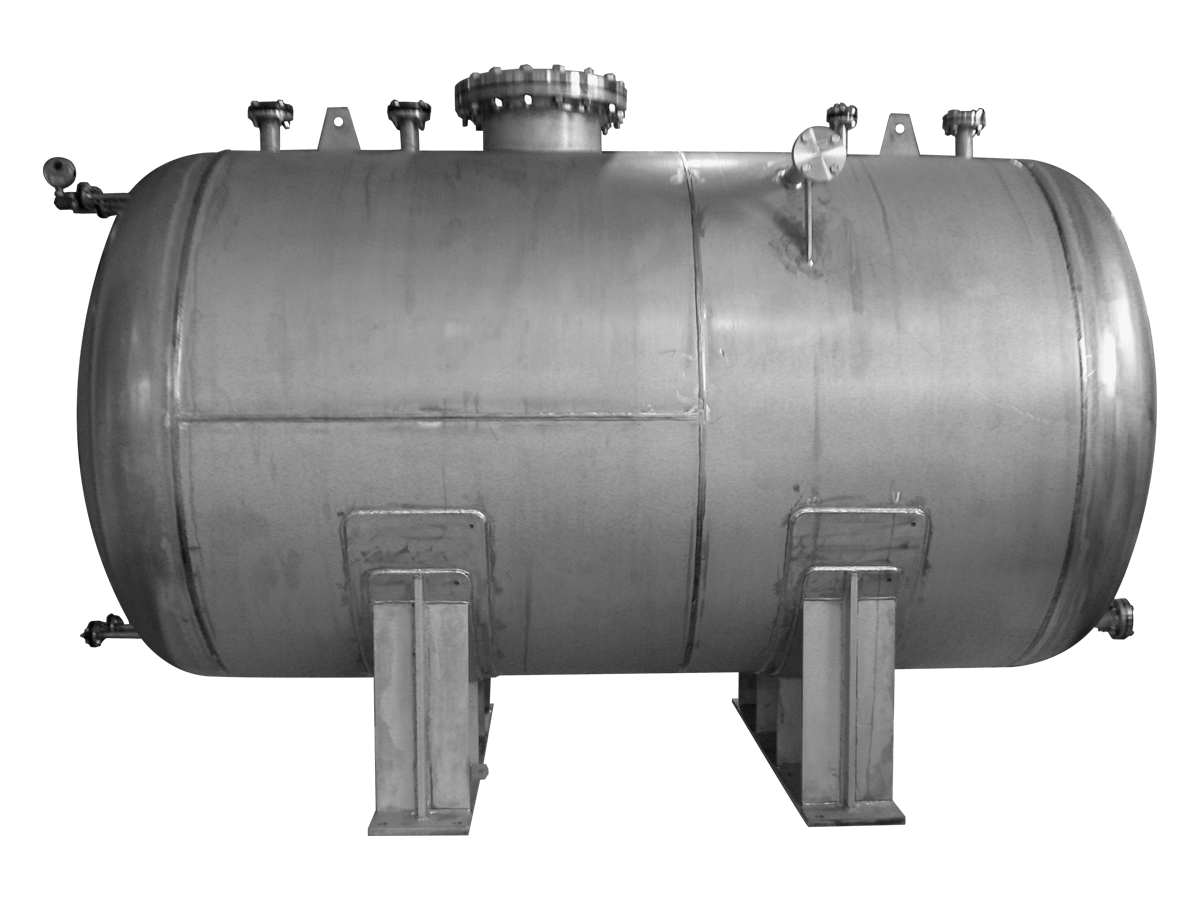

Pressure vessel

Sinergia has the internal capacity to design and manufacture a wide range of pressure vessels suitable not only for gases storage, but having specific functions such as:

- - Knock-Out drums

- - Condensate separators

- - Carbon towers

- - Membrane casings

- - Pulsation dampers

- - Filter casings

- - Heater casings

Different materials and construction codes can be considered.

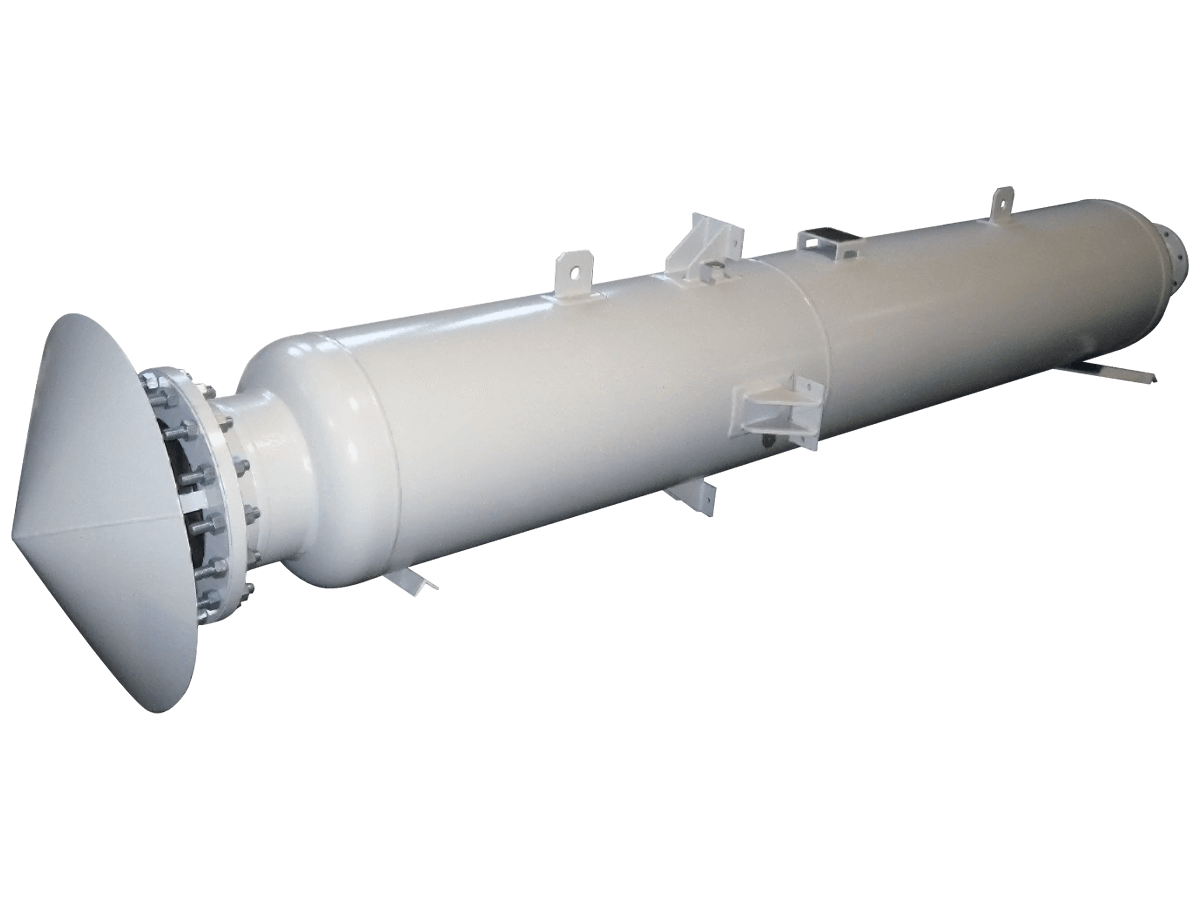

Noise reduction: silencer & canopy

Sinergia is particularly sensitive to the sound suppression of its packages, which means the health protection of workers. For this reason, the engineering team always takes care of this aspect of every project.

Silencers: Sinergia is endowed with calculation tools for the design and sound suppression simulation of its customized silencers that can be supplied under PED, ASME (U Stamp), and codes of construction.

Canopies: Sound suppression can also be extended to packages, where noisy equipment is installed, by enclosing it into canopies. Moreover, in certain applications and ambient, the canopy can give an advantage in terms of thermal insulation as well.